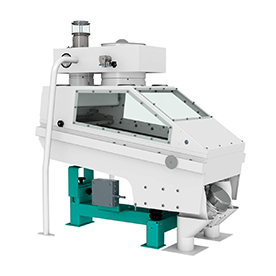

Rice Milling Industry

The rice milling industry involves the processing of harvested rice to remove the husk, bran, and germ, resulting in polished white rice. It plays a vital role in providing a staple food for millions of people worldwide. The industry utilizes advanced machinery and technologies to ensure efficient and high-quality rice production. Our rubber components also play important roles in the rice milling industry, including the use of sieve cleaning balls, rubber balls, barrel-shaped sieve cleaning balls, rubber sleeves, lift rubber sleeves, airlock rubber sleeves, rubber rings, anti-vibration mounts, rubber inspection caps, inspection caps, inspection caps with knob locks, and rubber cube roles.

Here's how they are utilized in the rice milling industry:

Sieve Cleaning Ball: Our Sieve cleaning balls, often made of rubber, are used in rice milling to clean the sieves or screens. These balls help remove impurities, such as broken grains, husks, and debris, from the rice during the sieving process.

Rubber Ball: Our Rubber balls are used in various stages of rice milling. They can be employed in machines such as destoners or separators to assist in the separation of impurities from rice based on differences in density or size.

Barrel-Shaped Sieve Cleaning Ball: Our Similar to regular sieve cleaning balls, barrel-shaped sieve cleaning balls are designed to clean barrel-shaped sieves specifically. They effectively remove foreign materials and ensure optimal sieving performance in the rice milling process.

Rubber Sleeve: Our Rubber sleeves are utilized in rice milling machinery to provide protection, sealing, and insulation. They can be found in equipment such as conveyor belts, augers, and chutes, helping to prevent grain spillage, reduce wear and tear, and maintain operational efficiency.

Lift Rubber Sleeve: Our Lift rubber sleeves are used in lifting mechanisms within rice milling equipment. These sleeves provide cushioning and help reduce vibrations and noise during the lifting and conveying of rice grains.

Airlock Rubber Sleeve: Our Airlock rubber sleeves are employed in rice milling systems where the transfer of rice between different stages or compartments needs to be airtight. These sleeves ensure a proper seal, preventing air leakage and maintaining the desired pressure differentials within the equipment.

Rubber Ring: Our Rubber rings are used in rice milling machinery for sealing purposes. They are commonly used in equipment such as rice hullers or polishers, providing an effective seal between rotating components to prevent grain leakage and maintain optimal processing conditions.

Anti-Vibration Mount: Our Anti-vibration mounts made of rubber are used in rice milling machinery to dampen vibrations. These mounts help reduce the transmission of vibrations from the machinery to the surrounding structures, minimizing noise levels and enhancing overall equipment stability and performance.

Rubber Inspection Cap: Our Rubber inspection caps can be found in rice milling equipment as access points for maintenance and inspections. These caps provide a seal, allowing for easy opening and closing when necessary, ensuring convenient access to critical components.

Inspection Cap with Knob Lock: Our Inspection caps with knob locks offer a secure sealing solution for inspection points in rice milling machinery. The knob lock mechanism allows for easy opening and closing, enabling efficient maintenance and inspections while maintaining the integrity of the equipment.

Rubber Cube Role: Our Rubber cube roles or rubber cubes are used as support elements, buffers, or vibration dampeners in rice milling machinery. They can be placed under equipment or used as shock-absorbing pads to minimize vibrations, noise, and impacts, thereby protecting the machinery and promoting smooth operation.

These rubber components play crucial roles in the rice milling industry by facilitating efficient cleaning, sealing, vibration control, and maintenance in various stages of the milling process. They contribute to improved productivity, product quality, and equipment longevity within rice mills.

Why our Products used in Rice Milling Industry ?

- The resilience of our balls are exceptional, thus it leads to an extra yield of the sieving process

- Our food grade rubber balls are made out of non-toxic chemicals

- The abrasion resistance is very high, thus the wear rate is minimal, leading to enhanced service life

- Our rubber ball cleaners are also fully fat resistance

- High Performance and cost saving innovatively designed rubber ball sieve cleaners

Anti-vibration mounts serve as indispensable assets in the Rice Milling Industry, effectively mitigating the impact of vibrations and shocks generated during the milling process. These specialized mounts provide crucial support and stability to the machinery, reducing excessive vibrations that can compromise the quality of milled rice and damage equipment. By absorbing and dampening vibrations, anti-vibration mounts help to minimize product loss, improve milling efficiency, and prolong the lifespan of machinery. With their ability to enhance precision and maintain consistent rice quality, anti-vibration mounts play a vital role in ensuring smooth operations and maximizing productivity in the rice milling industry.

Products :

| Rubber Ball | 16mm, 24mm, 26mm,30mm,32mm,35mm and 40mm, Drum Shape/Damru |

| Rubber Cube | 20mm, 20mm, 20mm |

| Anti Vibration Mount | 100mm*90mm 2. 96mm*96mm 3. 65mm*100mm |

| De-Stoner Rubber (Sleeve/Bag) | 150mm*Length 265mm |

| Rubber Sleeve (Airlock / Lift) | 75mm, 88mm, 100mm, 113mm, 150mm and 190mm |

| Rubber Ring | Suction Cup |